Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

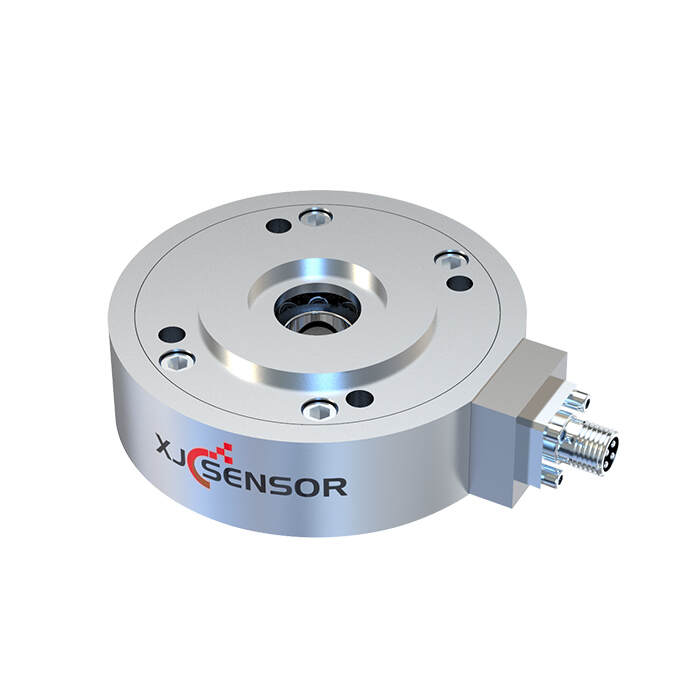

Understanding Membrane Tension Sensors: A Comprehensive Guide

In the realm of precision measurement and control, the membrane tension sensor plays a critical role. These sensors are essential in various applications where accurate tension measurement is required, such as in industrial processes, material testing, and even in medical devices. This blog will delve into the intricacies of membrane tension sensors, exploring their functions, applications, and why they are indispensable in many industries. Additionally, we will touch upon related technologies like flange tension sensors and how they complement the use of membrane tension sensors.

What is a Membrane Tension Sensor?

A membrane tension sensor is a specialized device used to measure the tension in a membrane, which can be a thin, flexible sheet of material. These sensors work by detecting the force applied to the membrane and converting it into an electrical signal that can be measured and analyzed. The sensitivity and precision make them ideal for applications where accurate tension control is crucial.

Key Features of Membrane Tension Sensors

- High Sensitivity: The sensors are highly sensitive and can detect even slight changes in tension.

- Precision: These sensors provide accurate measurements, essential for maintaining consistency in processes that require precise tension control.

- Durability: Constructed to withstand harsh environments, the sensors are durable and reliable over long periods.

How Membrane Tension Sensors Work

Membrane tension sensors operate based on the principle of strain measurement. When a force is applied to the membrane, it causes a deformation, which is detected by the sensor. This deformation is then converted into an electrical signal proportional to the tension in the membrane. The sensor typically uses strain gauges or piezoelectric materials to achieve this conversion.

Strain Gauges in Membrane Tension Sensors

Strain gauges are commonly used in thesensors due to their accuracy and reliability. They consist of a thin, metallic foil pattern that changes resistance when deformed. This change in resistance is measured and correlated with the tension in the membrane.

Piezoelectric Materials in Membrane Tension Sensors

Some sensors use piezoelectric materials, which generate an electrical charge when subjected to mechanical stress. These materials are highly sensitive and provide a quick response, making them ideal for dynamic tension measurements.

Applications of Membrane Tension Sensors

The sensors are used in various industries and applications where precise tension control is required. Below are some of the most common uses:

1. Industrial Process Control

In industrial settings, the sensors are crucial for monitoring and controlling tension in processes such as film extrusion, sheet manufacturing, and textile production. These sensors ensure that the tension is maintained within the desired range, preventing defects and ensuring product quality.

2. Material Testing

The sensors are widely used in material testing laboratories to measure the tensile strength of materials. By accurately measuring the tension applied to a membrane, researchers can determine the material's mechanical properties, such as its elasticity, yield strength, and ultimate tensile strength.

3. Medical Devices

In the medical field, the sensors are used in devices such as blood pressure monitors and ventilators. These sensors provide precise measurements that are critical for patient care, ensuring that medical devices operate within safe and effective parameters.

4. Aerospace Engineering

Aerospace applications often require highly sensitive and reliable sensors to measure tension in various components, such as membranes used in spacecraft and aircraft. The sensors are used to monitor and control these tensions, ensuring the safety and integrity of aerospace structures.

5. Robotics

In robotics, the sensors are used to measure and control the tension in flexible robotic components, such as artificial muscles or tendons. These sensors enable robots to perform delicate tasks that require precise control over force and movement.

Benefits of Using Membrane Tension Sensors

The use offers several advantages across different industries and applications. These benefits include:

1. Enhanced Precision and Control

The sensors provide highly accurate measurements, allowing for precise control over tension in various processes. This precision is essential in applications where even minor deviations can lead to significant issues, such as in material testing or medical devices.

2. Improved Product Quality

By ensuring consistent tension control, the sensors help maintain high product quality in manufacturing processes. For example, in the production of films or textiles, maintaining the correct tension prevents defects such as wrinkles, tears, or uneven thickness.

3. Increased Safety

In applications such as aerospace or medical devices, the sensors contribute to safety by providing reliable and accurate measurements. These sensors help prevent failures that could lead to catastrophic consequences, such as in aircraft components or critical medical devices.

4. Cost-Effective Solutions

While membrane tension sensors are highly advanced, they are also cost-effective, especially when considering the benefits they offer in terms of precision, reliability, and safety. By preventing defects and ensuring consistent quality, these sensors can lead to significant cost savings in the long run.

Integrating Membrane Tension Sensors with Other Technologies

The sensors are often used in conjunction with other technologies to enhance their functionality and effectiveness. One such technology is the flange tension sensor, which is commonly used in conjunction with the sensors in various applications.

The Role of Flange Tension Sensors

Flange tension sensors are designed to measure the tension in flanges, which are used to connect pipes or other components in a system. These sensors are often used in industrial settings where precise tension control is required in both the membrane and the flanges. By integrating flange tension sensors with membrane tension sensors, operators can achieve comprehensive tension monitoring and control throughout the entire system.

Example Integration

For instance, in a manufacturing process that involves both membranes and flanges, using both membrane and flange tension sensors allows for real-time monitoring and adjustment of tension in both components. This integration ensures that the entire system operates smoothly and efficiently, reducing the risk of failures or defects.

Choosing the Right Membrane Tension Sensor for Your Application

Selecting the right membrane tension sensor for your specific application involves considering several factors, including the type of membrane, the required sensitivity and accuracy, and the operating environment.

1. Membrane Material and Thickness

The material and thickness of the membrane play a significant role in determining the type of sensor needed. Thicker membranes may require sensors with higher sensitivity, while thinner membranes may need sensors that can accurately measure small changes in tension.

2. Operating Environment

Consider the environment in which the sensor will be used. For example, in harsh industrial environments, a sensor made from durable materials such as stainless steel may be required to withstand exposure to chemicals, moisture, and temperature fluctuations.

3. Required Sensitivity and Accuracy

Determine the level of sensitivity and accuracy needed for your application. High-precision applications, such as in medical devices or aerospace engineering, may require sensors with extremely high sensitivity and accuracy.

4. Integration with Other Systems

If your application involves integrating the membrane tension sensor with other systems, such as flange tension sensors, ensure that the sensors are compatible and can work together seamlessly.

Maintenance and Calibration of Membrane Tension Sensors

To ensure the long-term performance and reliability of membrane tension sensors, regular maintenance and calibration are essential. Proper maintenance can prevent sensor drift, reduce the risk of failures, and ensure that the sensors continue to provide accurate measurements.

Regular Inspections

Regularly inspect the sensors for signs of wear, damage, or contamination. Any issues should be addressed promptly to prevent inaccurate measurements or sensor failures.

Cleaning

Keep the sensors clean and free from debris or contaminants. In industrial environments, this may involve regularly washing the sensors with a suitable cleaning solution to remove dust, oil, or other residues.

Calibration

Periodic calibration is crucial to maintain the accuracy of membrane tension sensors. Calibration should be performed according to the manufacturer's recommendations or whenever the sensor is exposed to conditions that may affect its accuracy, such as extreme temperatures or mechanical shock.

Conclusion

Membrane tension sensors are vital tools in a wide range of industries, providing precise and reliable tension measurements that are essential for maintaining process control, ensuring product quality, and enhancing safety. Whether used in industrial manufacturing, material testing, medical devices, or aerospace applications, these sensors offer numerous benefits that make them indispensable in modern technology.