Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

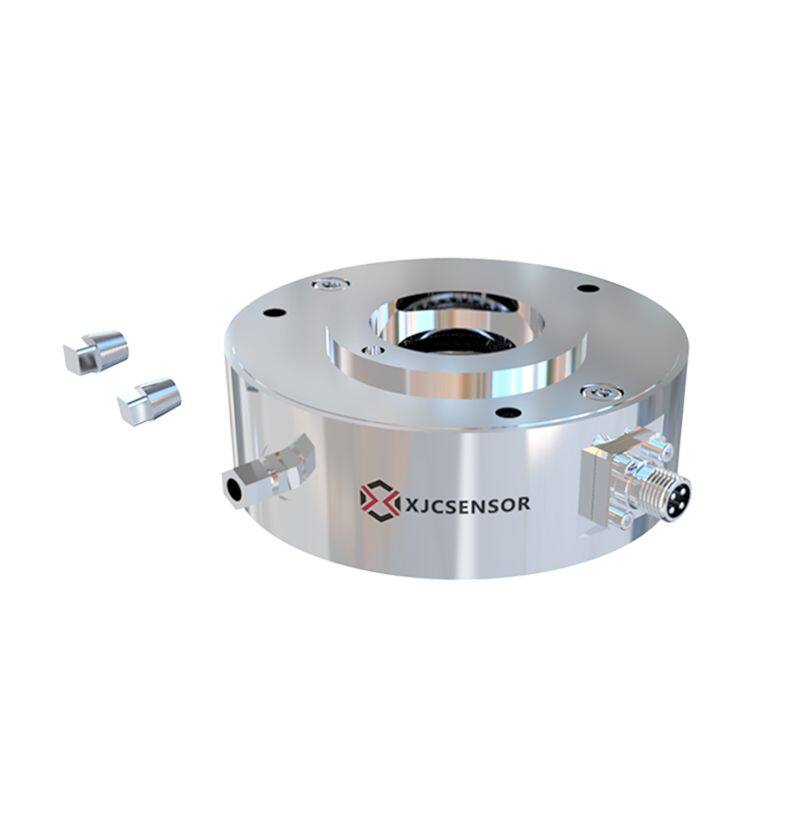

X-ZL06 Series Cantilever Tension Sensor

The X-ZL06 series cantilever tension sensor is specifically designed for precise tension measurement and control of various materials during processing. It is particularly suitable for applications involving paper, labels, tapes, battery electrodes, high-performance films, and other narrow materials. The sensor’s advanced technology guarantees a consistent detection signal, irrespective of the coil’s position on the roller.

X-ZL06 Series Cantilever Tension Sensor

Features of X-ZL06 Series Cantilever Tension Sensor:

- Easy installation with multiple installation modes

- Consistent detection signal regardless of coil position

- Incorporates advanced 10x anti-overload protection

- Minimal temperature drift, excellent non-linearity, and repeatability

- Compact size, minimizing installation space requirements

- Equipped with a standard M12*1 plug

Advantages of X-ZL06 Series Cantilever Tension Sensor:

- Process Control: The tension sensor is seamlessly compatible with automated systems, enabling real-time tension control and adjustment as per requirements. This integration facilitates smoother and more efficient production processes, enhancing overall productivity.

- Enhance Product Quality: The cantilever tension sensor plays a crucial role in enhancing product quality and consistency by ensuring precise tension control. This capability significantly reduces defects and waste in the manufacturing process.

- Durable Construction: The sensor is constructed using durable and robust materials, making it highly resilient and reliable, even in challenging industrial environments. Its sturdy build ensures longevity and consistent performance, even when subjected to demanding conditions.

Technical Parameter:

|

Rated Output |

1.0±10%mV/V |

Non-linearity |

0.2% F.S. |

|

Repeatability |

0.1%F.S. |

Zero Balance |

±2% F.S. |

|

Operating Temp Range |

-20~80°C |

Compensated Temp Range |

-10~40°C |

|

Temp Effect on Zero |

0.02%F.S/°C |

Insulation |

≥2000MΩ/100VDC |

|

Recommended Excitation Voltage |

5~10VDC |

Limit Load |

1000%F.S. |

|

Cable Size |

φ5x5m |

Protection Class |

IP65 |

How to Install the Cantilever Tension Sensor?

- Safety First: Turn off the equipment and follow safety guidelines;

- Choose the Location: Identify the installation point for the sensor near the material or web path;

- Sensor Check: Inspect the sensor and its components for damage;

- Position the Sensor: Securely mount the sensor inside or outside the machine panel, aligning the roller with the material path. (Note: The diameter of clearance holes on the machine wall panel should be at least 1.5mm larger than the shaft holes)

- Mounting Hardware: Use provided brackets and four screws for secure attachment to the shaft;

- Connect: Connect the sensor to monitoring equipment;

- Calibration: Calibrate the sensor for accurate tension measurements;

- Testing: Run tests to ensure accurate readings

- Adjust: Make any necessary adjustments based on test results.

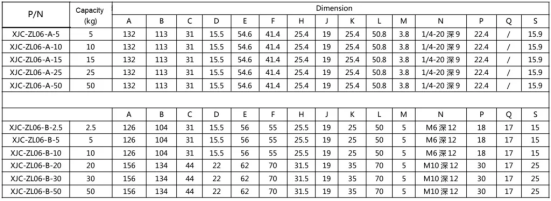

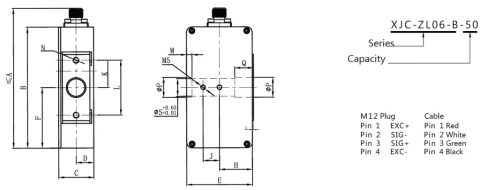

Dimensions

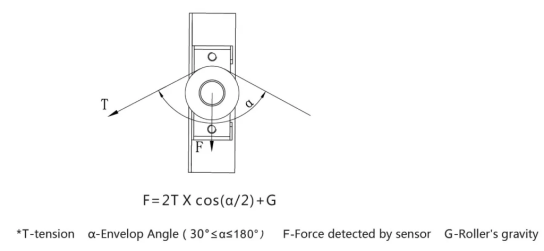

Force calculation

Installation

Two installation methods are as follows:

Note: Insert the sahft and roller components provided by customer into the cantilever tension sensor. Make sure the sensor’s housing and the machine wall panel will not be interfered by neither the shaft nor the roller components. The diameter of clearance holes on the machine wall panel should be at least 1.5mm larger than the shaft holes, and then fasten the four screws firmly to the shaft.

Naming Rules